Quality

Initial sample inspection

Prior to the delivery of the filter series, you receive a prototype that has been manufactured in accordance with the purpose of application and pointed out directives. These specifications are the basis for the inspection requirements.

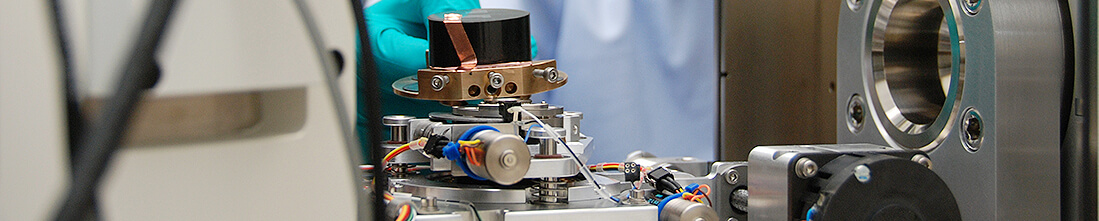

Manufacturing-related inspection

The amount of inspection is determined individually based on the respective requirements. We carry out dimensional conformance inspections of individual components that are merged into a single unit. If the application of special materials is required, the inspection of the raw materials includes alloy elements and mechanical parameters. In order to detect faults in the mesh or check welded and bonded connections we apply the bubble point test. If the maximal load-bearing capacity is to be determined with respect to the differential pressure, the pressurisation is applied until collapse.

Laboratory

We cooperate with qualified service providers who carry out all required inspections, such as:

Materials characterisation

Schmitz Metallographie GmbH

in D-52134 Herzogenrath

www.schmitz-metallographie.de

Quality management system in accordance with DIN EN ISO 9001:2015

Our highly motivated and highly skilled employees are continuously involved in the process-oriented quality management system. Since 2011, we are certified in accordance with DIN EN ISO 9001. Our services are checked in audits on a regular basis. Not only quality, but also occupational safety and environmental protection are of utmost importance to us.